The Single Strategy To Use For Premier Aluminum Llc

The Single Strategy To Use For Premier Aluminum Llc

Blog Article

What Does Premier Aluminum Llc Do?

Table of ContentsThe 30-Second Trick For Premier Aluminum LlcThe smart Trick of Premier Aluminum Llc That Nobody is Talking AboutA Biased View of Premier Aluminum LlcThe Main Principles Of Premier Aluminum Llc

(https://pubhtml5.com/homepage/lekm/)Typically, a buyer's primary duty was to discover professional and receptive distributors. In some instances, purchasers presumed that any type of supplier going to contractually satisfy the purchase need was qualified. Making use of reduced expense and unqualified suppliers can cause quality concerns, and lost time and cash in the long run. To help you with the process, here are some points to consider when picking the appropriate steel spreading provider.

A firm that only makes use of the investment spreading process will certainly try to market you on why that procedure is best for your application (Foundries in Wisconsin). What if using the sand casting procedure is best for you and your demands? Instead, search for a supplier that offers a variety of casting processes so the best option for YOU is picked

If collaborating with a single source for all of your spreading needs is essential to you, the supplier requires to be varied in its capabilities. When incorporated with other incorporated abilities, this can assist streamline and compress the supply base. When choosing the best casting distributor, cautious factor to consider should be provided to quality, service, and rate.

The smart Trick of Premier Aluminum Llc That Nobody is Discussing

Purchasers progressively pick spreading suppliers that have machining capabilities. This can avoid conflict if defects are uncovered during machining. If a third celebration is machining, it may lead to "finger-pointing" about who is at mistake. Is it a casting issue or a machining concern? If the casting vendor finds a concern during machining, the problem is fixed faster with no conflict over whose fault it is.

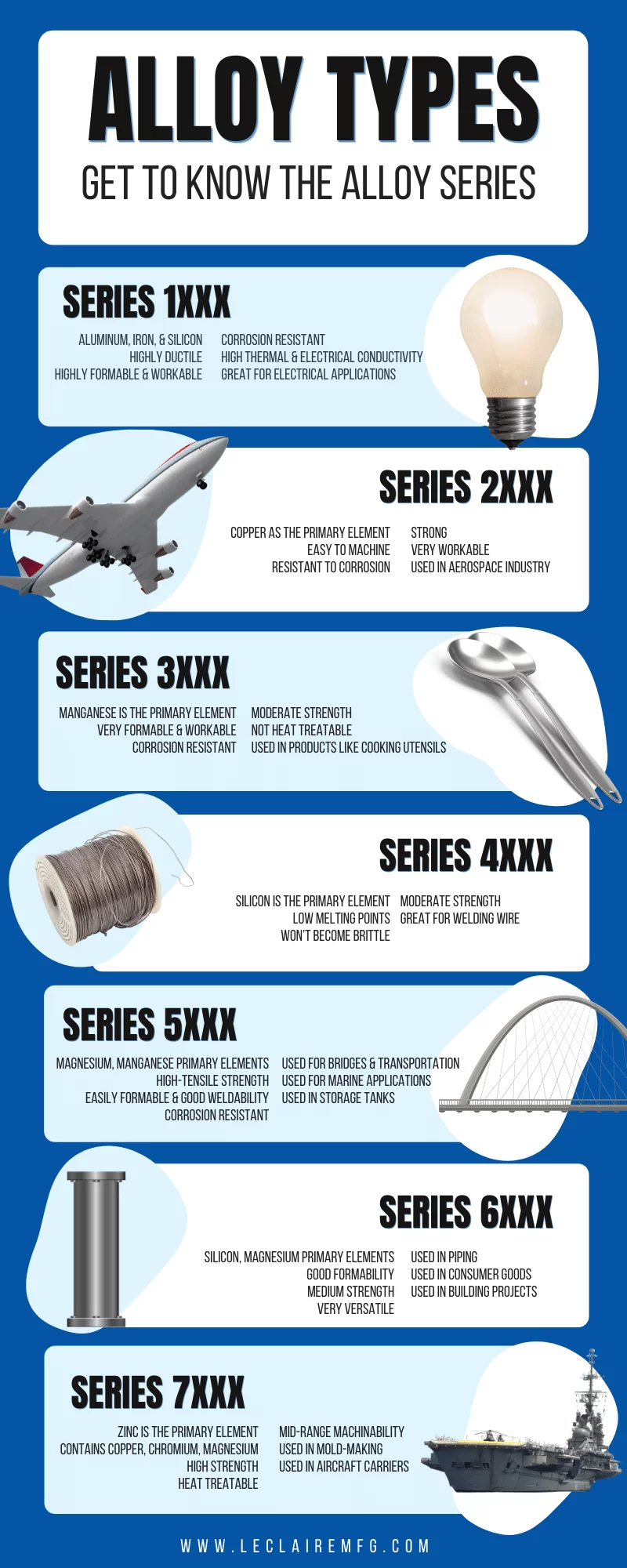

Trouble or no, incorporated machining streamlines the supply chain and minimizes managing time and delivery cost prior to the item makes it to the consumer. What do you require from your casting supplier? Are you trying to find someone to just deliver a steel part to your doorstep or do you need extra? As an example, if you do not have internal metallurgy know-how, confirm that the distributor can offer advice in picking the correct alloy based upon your specific application - Foundry near me.

Some shops are limited or specialized. Make sure the provider can fulfill all your product or alloy needs to eliminate the requirement for several vendors.

The Buzz on Premier Aluminum Llc

Research the supplier's web site. Talk to a sales representative or service affiliate.

Aluminum is likewise lightweight and has good rust resistance, navigate to this website making it ideal for applications where weight and durability are necessary elements. Furthermore, aluminum spreading is a cost-effective technique of production, as it needs less power and sources than other approaches. Iron spreading, on the other hand, entails pouring liquified iron into a mold and mildew to produce a wanted form.

Premier Aluminum Llc - The Facts

Iron spreading is additionally able to hold up against heats, making it suitable for usage in applications such as engine parts and industrial equipment. Iron spreading can be much more expensive than aluminum spreading due to the higher cost of raw materials and the energy required to melt the iron. When making a decision between aluminum spreading and iron casting, it is very important to think about the specific demands of the application.

In verdict, both light weight aluminum spreading and iron casting have their very own unique benefits and downsides. There are three sub-processes that fall under the category of die spreading: gravity pass away spreading (or irreversible mold casting), low-pressure die casting and high-pressure die spreading. To obtain to the completed product, there are 3 main alloys used as die spreading material to select from: zinc, aluminum and magnesium. Report this page